Tokamak – Magnets

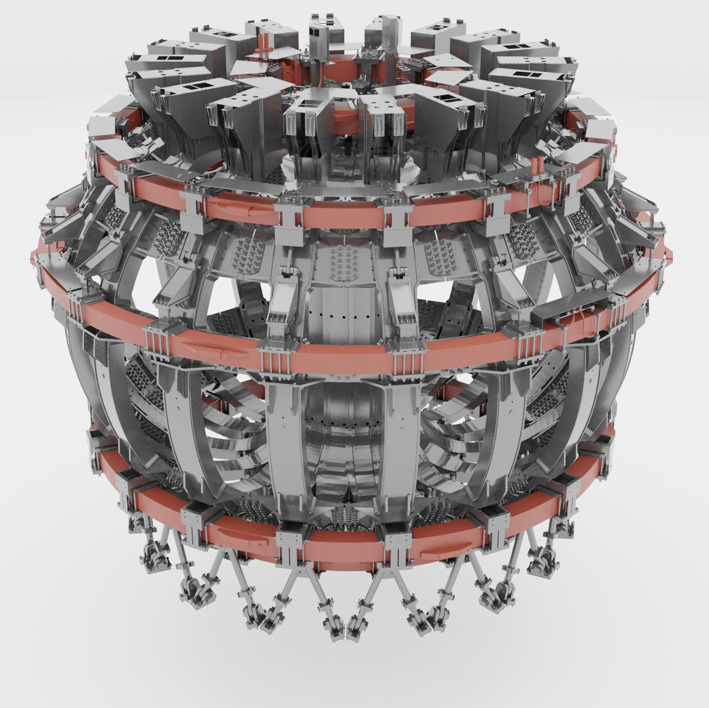

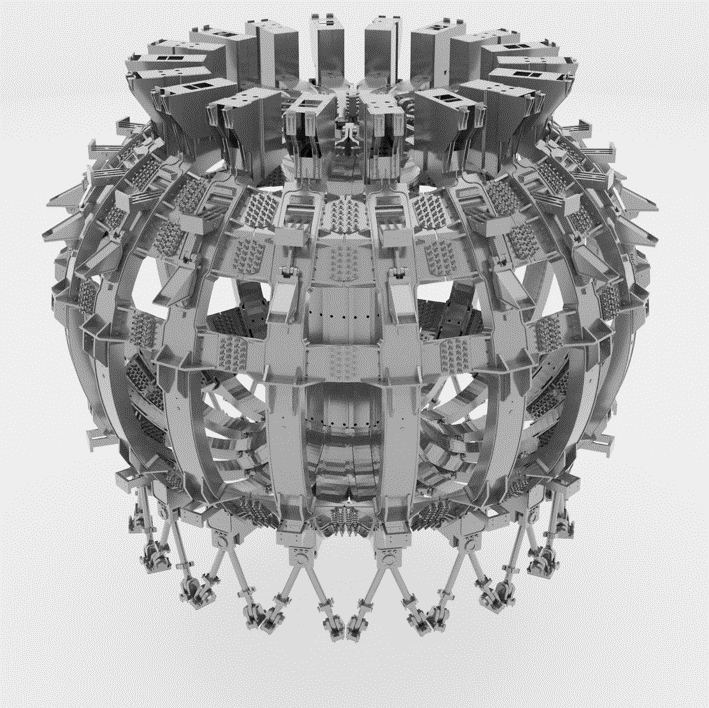

The superconducting coil system consists of

- 18 NbTi toroidal field (TF) coils;

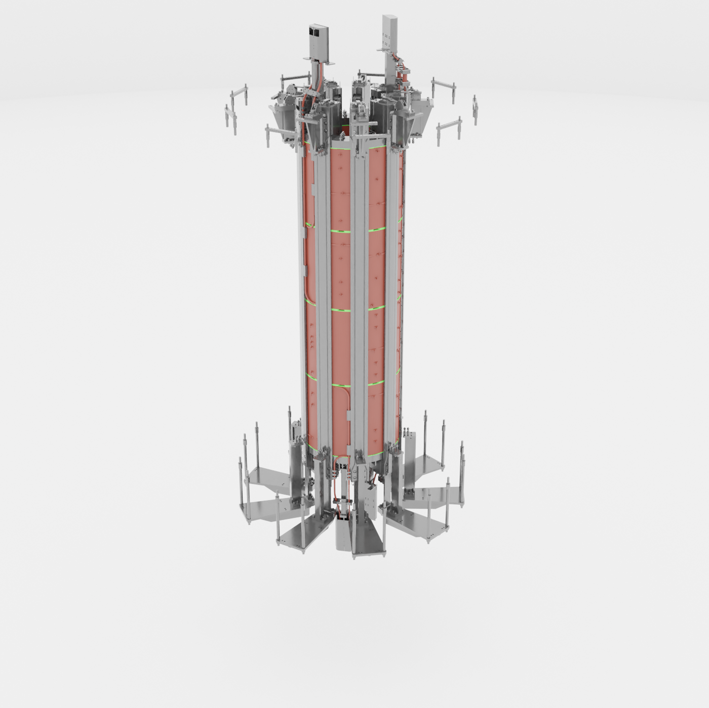

- a Nb3Sn central solenoid (CS) made from 4 coil modules;

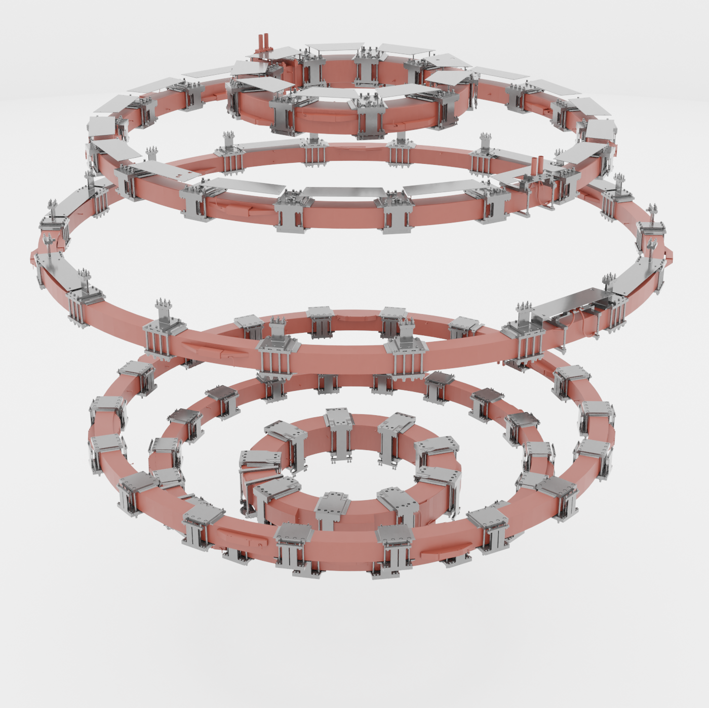

- 6 NbTi equilibrium field (EF) coils;

- common components, such as coil feeders and current leads.

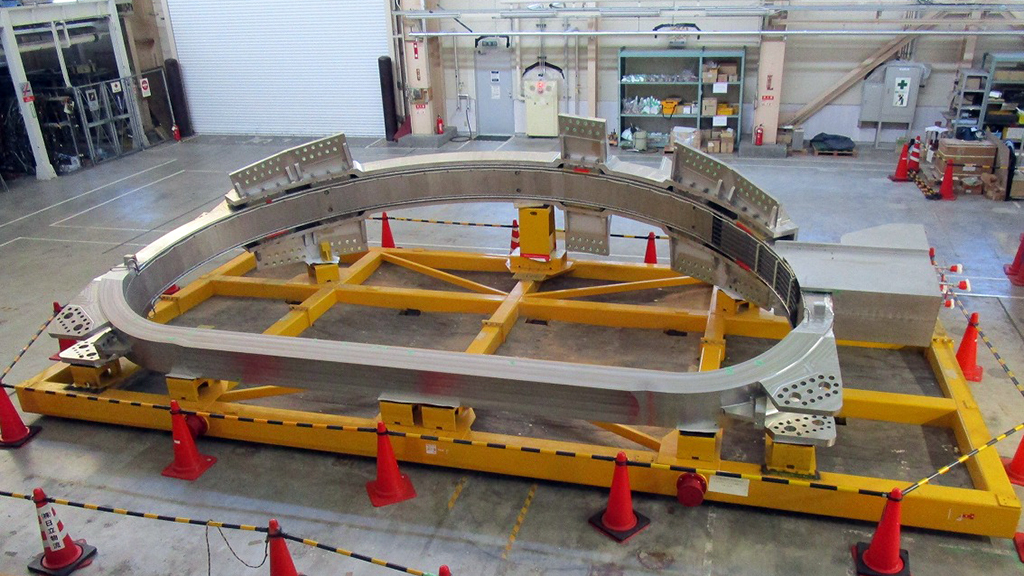

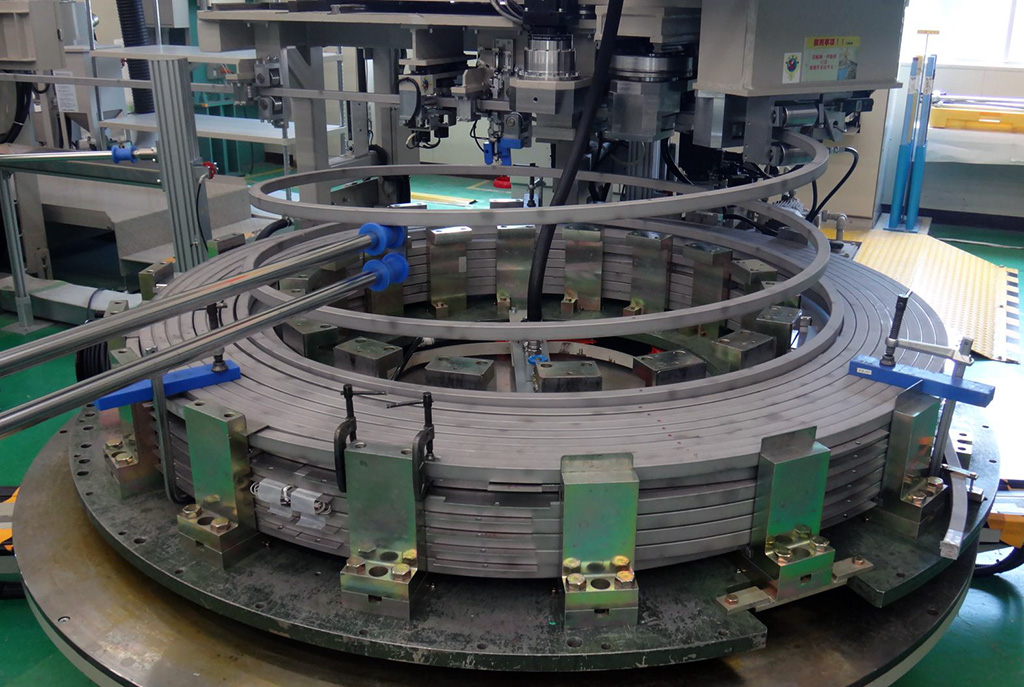

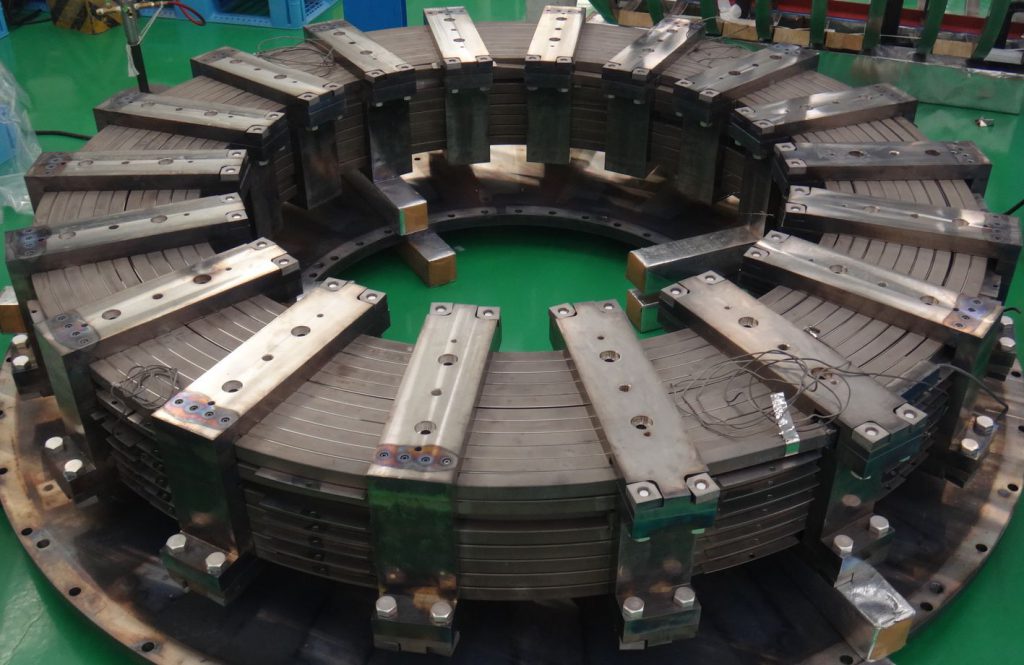

The D-shaped TF coils were wound, by ASG of Genoa (for Italy) and Alstom of Belfort (for France), from a square steel-jacketed NbTi cable-in-conduit conductor made by ICAS of Frascati (for Italy) using strand made by Furukawa Electric of Nikko (for Europe), force-flow-cooled by supercritical (~4K) helium. The winding pack is inserted in a stainless steel casing, machined and assembled by Walter Tosto of Chieti (for Italy), with additional cooling channels to aid magnet cool-down.

The Toroidal Field Magnet

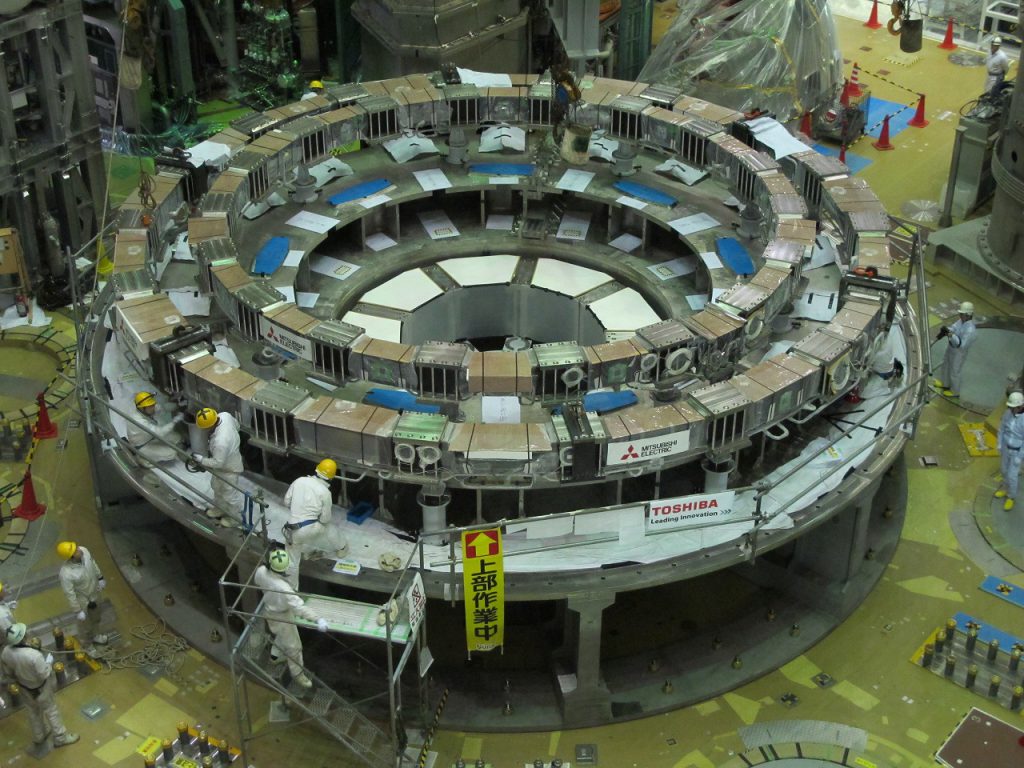

The Equilibrium Field Coils

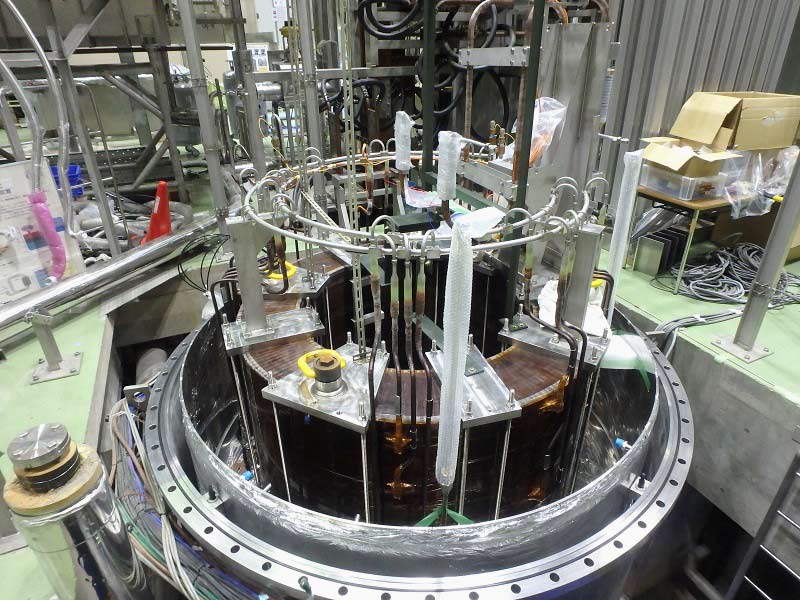

The Central Solenoid

The TF coils are wedged together over their straight section to support centralising forces. Overturning moments on the coils are supported by keys between the casing in the upper and lower inboard curved regions. There is an outer intercoil structure, manufactured by SDMS in St. Romans (for France), in the region between the vessel ports. This consists of bolted shear plates with friction and insulated surfaces contacting the TF coil case.

The TF coil casing includes a gravity support, manufactured by Alsyom in Tarbes (for France), composed of struts which are bolted to the cryostat base.

Prior to shipment to Japan the TF coils were tested in CEA, Saclay at 4K and full current. The coils were then pre-assembled with their intercoil support structure by CEA, Saclay and packaged for overseas travel. Two spare coils have been manufactured to reduce the risk of delay in delivery of the 18th coil to Japan, and to minimise delay later in case of a failure during operation.

The CS uses a conductor similar to that used for ITER and using identical strand as for the ITER TF conductor. The conductor is a circular Nb3Sn cable in square conduit cooled by supercritical helium. The EF coil conductor is a circular NbTi cable in square conduit cooled by supercritical helium. Both conductors have been manufactured and tested on site at JAEA, Naka, using stand from Furukawa Electric of Nikko.

The four independent modules of the CS can be powered independently. All structural and operational loads are reacted internally. The CS is supported from the bottom of the TF coil casing. The EF coils are clamped to the TF coil case. They are self-supporting with respect to radial (in-plane) loads.

There are other (normal conducting) magnet coils used inside the vessel to control plasma instabilities and to compensate for unavoidable manufacturing and assembly errors in the superconducting magnets. These are part of the in-vessel components.